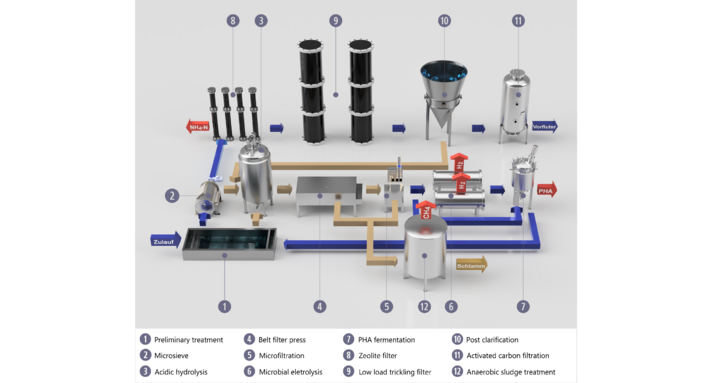

The diagram of the KoalAplan project shows how municipal wastewater treatment plants can recover ammonium, hydrogen and polyhydroxyalkanoates (PHA) in addition to a classical wastewater treatment.

The municipal wastewater is led into the primary clarifier, where sedimentation is used to separate the solids from the raw wastewater. Subsequently, even finer suspended solids are filtered out of the contaminated water in a micro-screen.

The liquid phase and the separated solids are then routed as two different material streams:

The main stream consists of the wastewater and is further purified. Downstream of the microscreen is a zeolite filter is installed. This filter is used for ammonium recovery and operates on the principle of ion exchange. The removal of residual carbon and the conversion of residual ammonium nitrogen to nitrate nitrogen is then conducted by using a low load trickling filter. The secondary settling stage is used to remove residual solids or biomass that has built up in the previous trickling filter. The particles filtered out here are returned and added to the acid hydrolysis. Finally, the main stream can pass through an activated carbon filter for micropollutant removal; this step is optional before it is fed to the receiving water.

The second material stream, the biorefinery, focuses on recycling the particulate organic carbon from the wastewater. After microscreening, the sludge enters an acid hydrolysis unit. There, the carbon is converted into volatile organic acids for further processes.

The next two steps, belt filter press and microfiltration, are used to separate the solids. These particles are fed to the anaerobic sludge treatment where the sludge is stabilized. Among other compounds, methane is produced in this process. Hydrogen is obtained in the subsequent microbial electrolysis, which can be used as an end product or for further biotechnological synthesis.

The wastewater then flows through a PHA fermentation, whose task is to produce the biopolymer polyhydroxybutyric acid (PHB), from organic carbon using microorganisms. Contamination of the remaining water cannot be guaranteed. Therefore, unlike the wastewater from the main stream, it cannot be discharged to the receiving water. The water produced here is fed back into the primary clarifier and passes through the cycle again.