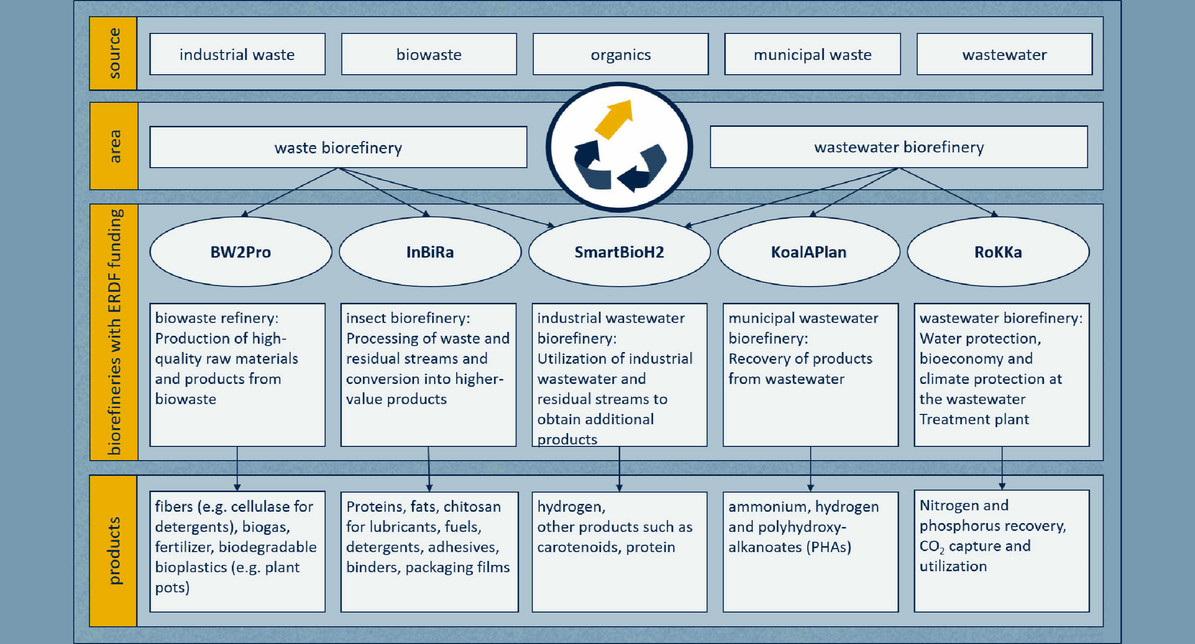

The Ministry for the Environment, Climate and Energy Sector of Baden-Württemberg, together with the EU Commission, is funding the construction and implementation of five modular biorefineries as part of the ERDF funding programme "Bio-Economy Bio-Ab-Cycling".

In a sustainable bioeconomy, wastewater and waste treatment plants become important suppliers of raw materials. The aim is to obtain raw materials for products from waste and wastewater, which are then returned to the economic cycle and put to economic use.

In sewage treatment plants, for example, platform chemicals such as amino acid, ammonium or hydrogen can be extracted from wastewater. Products can also be obtained from biowaste, such as fibres for use in flower pots or polyhydroxyalkanoate (PHA), a biodegradable substance used to produce biobased plastics, or fertiliser and biogas.

Through the funded projects, processes that already work on a small scale are combined and tested in demonstration and pilot plants in the sense of a refinery. This is an important intermediate stage before the processes are used in municipalities or industry.

A total of about 19 million euros in funding will be used, of which about 7,7 million euros will come from the European Union and about 11,2 million euros from the State of Baden-Württemberg. In addition, the state is funding the Expert initiative for the recovery of raw materials from waste and waste water as an innovation ecosystem, i.e. as a spatially limited cluster in which various players network with each other to jointly drive innovation.

The following projects are funded:

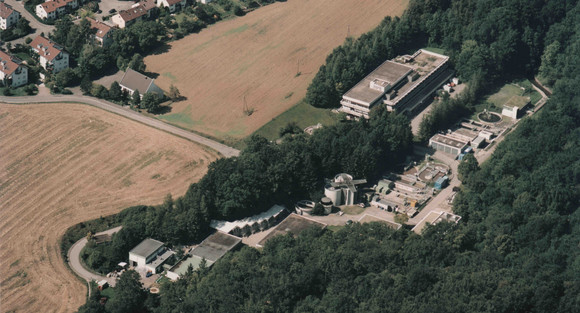

At the University of Stuttgart's teaching and research wastewater treatment plant in Büsnau, three products are extracted from municipal wastewater: Ammonium, hydrogen and polyhydroxyalkanoates (PHA).

A decisive goal of the project is that the utilisation of the particulate organic carbon of the municipal wastewater does not only consist of the production of the comparatively cheap and climate-relevant gas methane, as has been the case so far, but that more sustainable products are created. In parallel, the largely particle-free wastewater is purified in the main stream. Ammonium is recovered here, which can be used as nitrogen fertiliser for agriculture.

Most of the particulate organic carbon is recovered by sedimentation in the primary settling stage. More than 50 per cent of the total organic carbon in municipal wastewater is bound in solids and is not present in solution. The particles still present in the primary treatment effluent are separated from the municipal wastewater with the help of a microscreen.

Hydrolysate can be obtained from the particulate organic carbon by biochemical splitting with water. The hydrolysate is rich in organic acids and is bioelectrochemically converted to hydrogen and CO2 in a novel reactor system.

In a further step, the material flows produced in the previous processes (hydrolysate) are converted into polyhydroxyalkanoates (PHA). Polyhydroxyalkanoate can be used to produce bio-based plastics.

Project coordination:

DVGW Research Unit at the Engler-Bunte Institute of the Karlsruhe Institute of Technology (KIT) DVGW-EBI

Professor Dr. Harald Horn

Project partner:

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

- Clausthal University of Technology

- Hamburg University of Technology, Institute of Technical Microbiology

- State Agency Umwelttechnik BW GmbH

- University of Stuttgart, Institute for Sanitary Engineering, Water Quality and Solid Waste Management – Teaching and Research Sewage Treatment Plant

- University of Southampton (Associated Partner)

Funding/Total amount: approximately 2,3 Millionen Euro

EU funds: approximately 940.000 Euro

State Funding: approximately 1,4 Millionen Euro

Further information (only in German)

Umwelttechnik BW: KoalAplan – Municipal wastewater as a source of raw materials

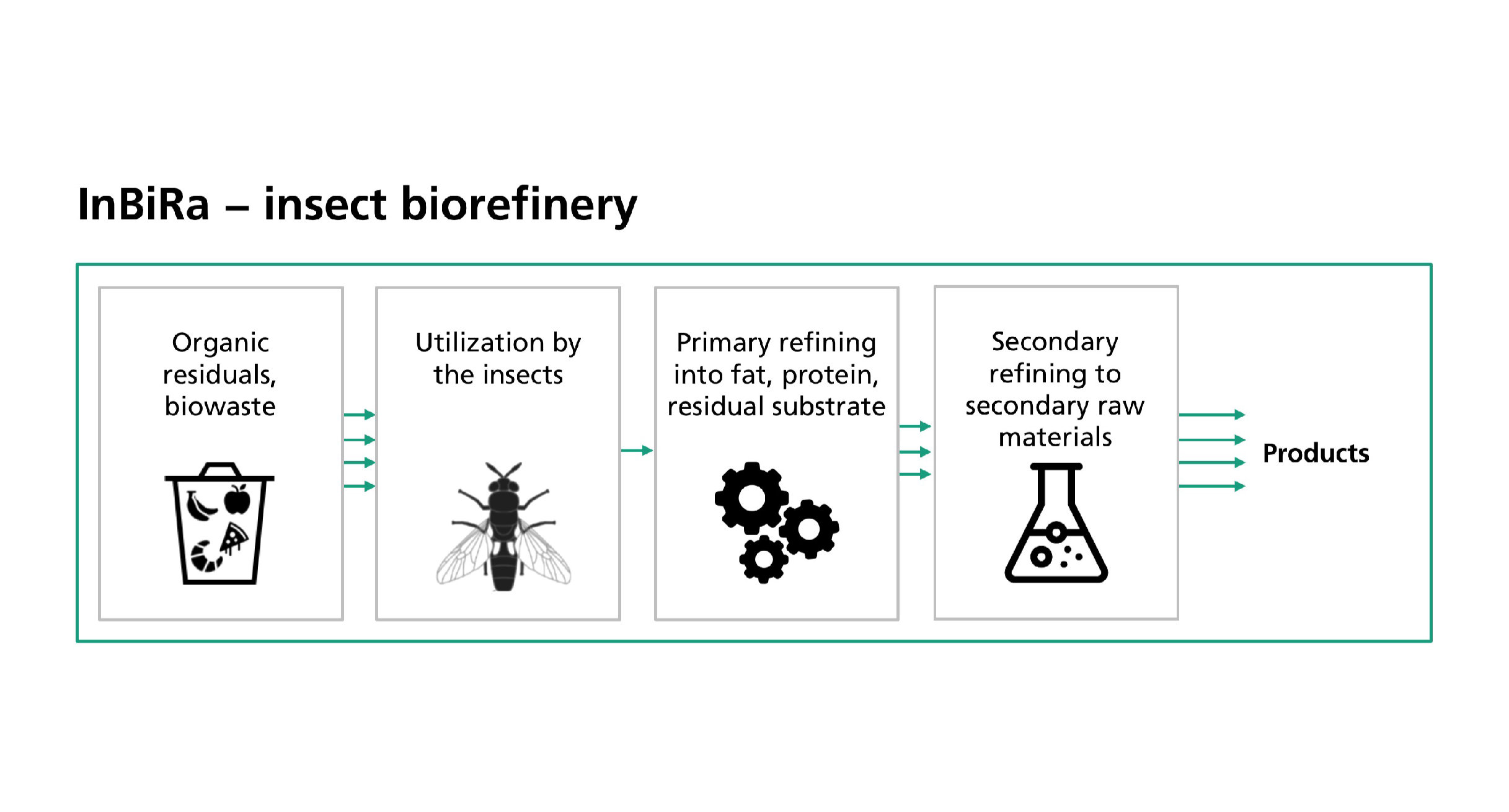

In the InBiRa project, an insect biorefinery is being built for the first time, in which waste and residual streams are converted into new high-quality products.

This is made possible by the insect larvae of the black soldier fly. They contain proteins, fats and chitin, from which new products can be made.

First, the waste and residual streams from the food sector, for example overstocked food or leftovers from canteens, are processed in such a way that the insect larvae can utilize them efficiently and grow quickly. The larvae are then processed further. The insect biomass is rich in fat and proteins and is separated into different fractions in the insect biorefinery:

- The crude fat can be converted into lubricants, fuels or cleaning agents. The particular advantage is that the crude fat has a fatty acid composition similar to that of coconut or palm kernel oil due to its high proportion of lauric acid, thus offering an alternative to tropical oils.

- The protein content of the insects is used in the production of adhesives, binders, coatings or packaging films. The residues from the processing of the insect larvae are examined for other ways of utilization - such as the extraction of chitosan or the use as fertilizer. Chitosan is a degradable biopolymer that can be used to produce protective films, for example. Among other things, it can be used to coat clothing.

The InBiRa project is investigating the feasibility of manufacturing and the marketability of various products from the refined insect larvae in close cooperation with potential user groups. In addition, the entire manufacturing process will be subjected to a comprehensive sustainability assessment and life cycle assessment.

Project coordination:

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Dr. Susanne Zibek

Project partner:

- BIOPRO Baden-Württemberg GmbH

- Hermetia Baruth GmbH

- ifeu - Institute for Energy and Environmental Research Heidelberg gGmbH

- University of Stuttgart, Institute for Interfacial Process Engineering and Plasma Technology

- University of Stuttgart, Institute for Sanitary Hidraulic Engineering, Water Quality and Waste Management

- PreZero Foundation & Co. KG (Associated partner)

Total amount: approximately 4 million euros

Funding: approximately 3.8 million euros

EU funds: approximately 1.6 million euros

State funding: approximately 2.2 million euros

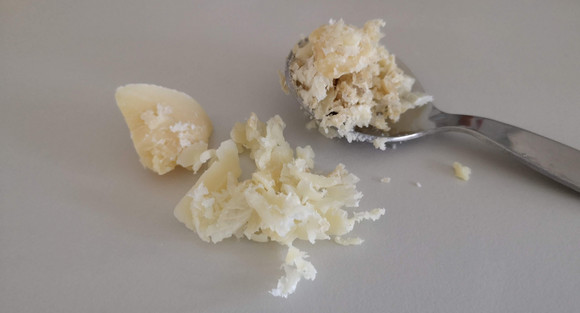

In the organic waste refinery „BW2Pro“, one ton of biowaste is to be processed daily into high-quality products and raw materials.

By means of high pressure and high temperatures, the biowaste is split and separated into a fibrous solid fraction and a liquid fraction. Almost all parts of the biowaste are further processed or used.

Medium fibers are pressed into products such as flower pots. Short fibers serve as a carbon source for the production of cellulase, which is contained in many detergents, for example.

The liquid fraction is fermented to produce biogas, and its digestate is used as fertilizer. Part of the liquid fraction is used to produce biodegradable bioplastics.

The BW2Pro project will be integrated on an already existing biogas plant of the Waste Management Rems-Murr. Waste Management Rems-Murr was involved in the planning of the project consortium at an early stage. Associations also support the project locally.

The project shows how biowaste can be recycled in municipal biogas plants. Here, the modular structure of the project is of great importance, as individual modules could be integrated on existing plants and thus the existing technology can be supplemented.

Project coordination:

University of Stuttgart, Institute for Sanitary Hidraulic Engineering, Water Quality and Waste Management

Dr. Claudia Maurer

Project partner:

- BIOPRO Baden-Württemberg GmbH

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

- Offenburg University of Applied Sciences, Faculty of Mechanical and Process Engineering

- ifeu - Institute for Energy and Environmental Research Heidelberg gGmbH

- NOVIS GmbH University of Hohenheim, State Institute for Agricultural Engineering and Bioenergy

- University of Stuttgart, Institute for Energy Economics and Rational Use of Energy

- University of Stuttgart, Institute for Interfacial Process Engineering and Plasma Technology

- University of Stuttgart, Institute for Plastics Technology

- Waste Management Rems-Murr (Associated partner)

Total amount: approximately 5,95 millions Euro

Funding: approximately 5,87 millions Euro

EU funds: approximately 2,38 millions Euro

State funding: approximately 3,49 millions Euro

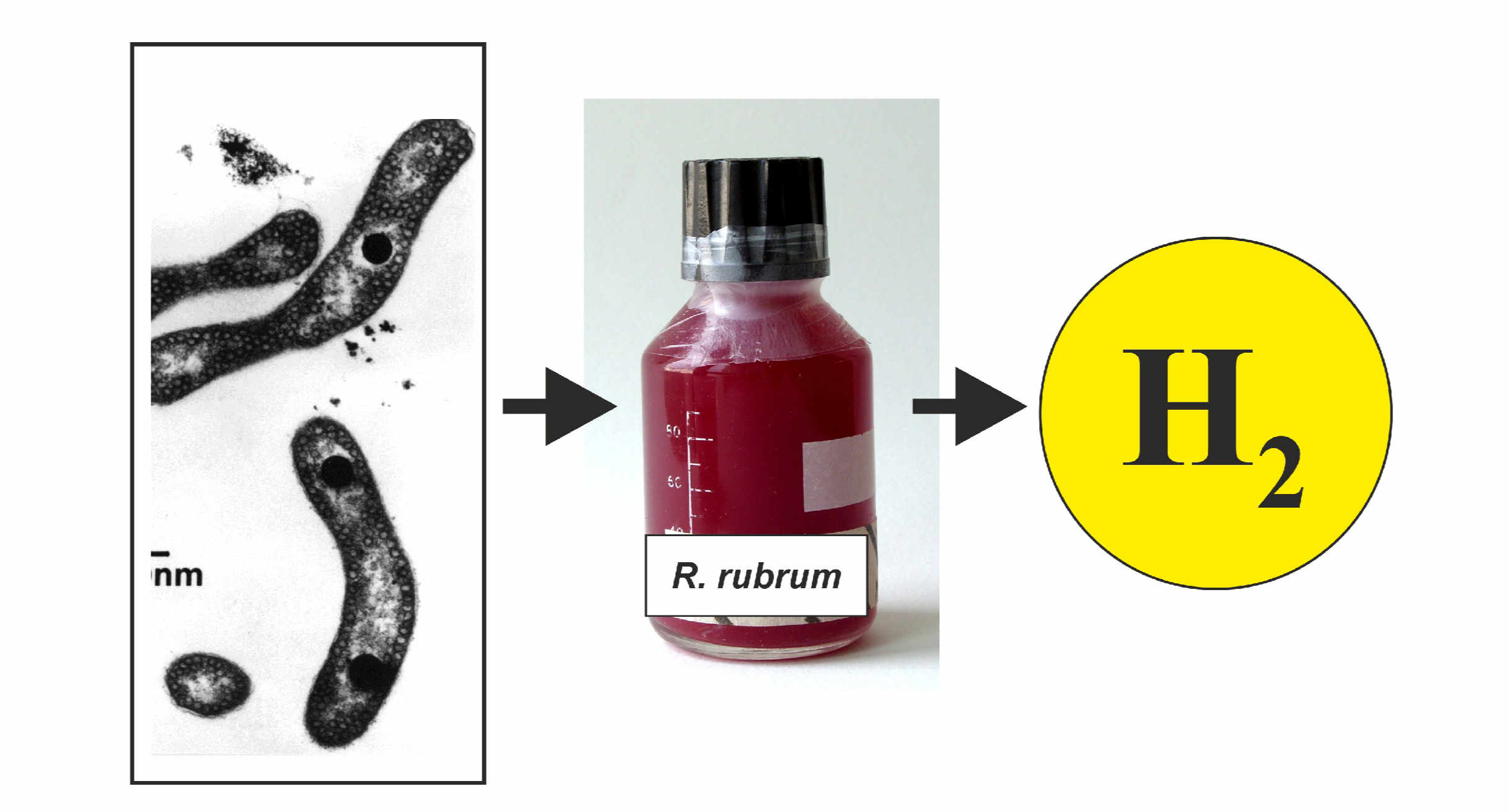

In the SmartBioH2-BW project, a biorefinery is to be integrated into the existing industrial environment of Evonik Operations GmbH in Rheinfelden - using industrial wastewater and residual material streams generated there.

The biorefinery is based on two processes for biotechnological hydrogen production that are linked together:

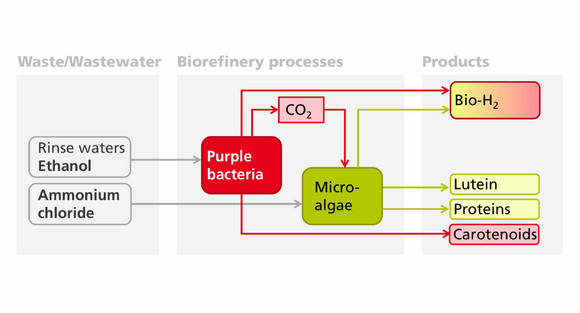

Hydrogen (H2) and other products such as carotenoids are produced in a closed bioreactor using purple bacteria. Carbon dioxide (CO2) is produced as a by-product.

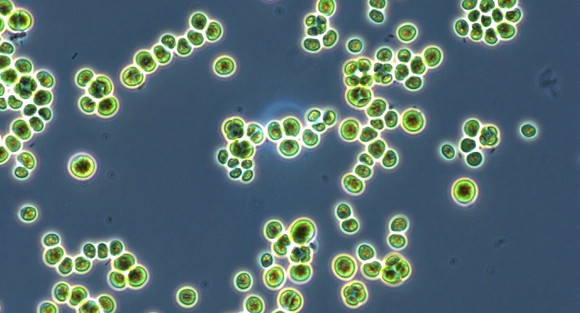

The carbon dioxide is fed to the connected microalgae plant. There it is bound in the algae biomass - releasing further hydrogen or other products such as proteins or lutein. In addition to binding the carbon dioxide, the process serves to increase the hydrogen yield and expand the biorefinery's product range.

The biorefinery is to be analyzed and optimized according to ecological, economic and social criteria throughout the entire planning and development process. The project partners are developing a holistic evaluation system that can be transferred to other "biorefineries" and that can be used to record the relevant environmental effects and economic relationships.

Project coordination:

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Dr. Ursula Schließmann

Project Partner:

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA

- University of Stuttgart, Institute of Biomaterials and Biomolecular Systems

- University of Stuttgart, Institute for Energy Efficiency in Production

- Evonik (Associated partner)

Total amount: approximately 3.0 million euros

Funding: approximately 3.0 million euros

EU funds: approximately 1.2 million euros

State funding: approximately 1.8 million euros

Wastewater treatment plants are already working very well today when it comes to protecting water bodies. What is new about the concept of the "RoKKa" project is that raw materials are extracted from wastewater, just like in a biorefinery. At the Erbach municipal wastewater treatment plant, the production of valuable materials at wastewater treatment plants is being researched and demonstrated in innovative pilot plants. Nitrogen recovery, phosphorus recovery, CO2 capture and utilization, electrosynthesis and microalgae production are used. RoKKa is testing the bioeconomic approaches at the site of the municipal wastewater treatment plant in Erbach.

Nutrients are extracted from the sludge water separated after digestion, which can be used either as fertilizer in agriculture or directly for algae production. The CO2 in the biogas from the digestion process is separated and processed into a basic chemical.

An important aspect of RoKKa is that, in addition to water protection, the project also includes climate protection and the bioeconomy as objectives for the operation of wastewater treatment plants. In particular, nitrous oxide emissions from wastewater treatment plants, which are 265 times more harmful to the climate than carbon dioxide, are to be reduced by the work in RoKKa. The RoKKa demonstration project is intended to bring about nationwide transferability of the bioeconomic approaches in Baden-Württemberg's wastewater treatment plants and beyond. The wastewater treatment plant in Steinhäule, which is involved in the RoKKa project, is reviewing the transferability of the bioeconomic solutions to another site directly in the project.

Project coordination:

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Dr. Marius Mohr

Project partner:

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB – BIOCAT

- DEUKUM GmbH

- Nanoscience for Life GmbH & Co KG

- SolarSpring GmbH

- City of Erbach

- State Agency Umwelttechnik BW GmbH

- University of Kassel, Department of Urban Water Management

- University of Stuttgart, Institute of Interfacial Process Engineering and Plasma Technology

- Technical University of Kaiserslautern, Department for Resource Efficient Wastewater Technology

- Steinhäule Wastewater Treatment Plant

Total amount: approximately 3.93 million euros

Funding: approximately 3.83 million euros

EU funds: approximately 1.57 million euros

State funding: approximately 2.26 million euros

Further information (only in German)

Umwelttechnik BW: RoKKa – Raw material source sewage treatment plant

The Expert Initiative for the recovery of raw materials from waste and wastewater aims to network the various project partners within the framework of the ERDF funding programme „Bio-Ab-Cycling“ as an innovation ecosystem, i.e. as a spatially limited cluster in which various players network with each other to jointly drive innovation.

The close exchange of information and experience during implementation of the demonstration and pilot projects supports the progress and makes the results accessible to other stakeholders.

In order to achieve successful market acceptance of the recovered products, project partners, interested stakeholders and further parties are supported in developing utilisation paths for the products and their sales opportunities.

The different approaches of biorefineries and the gained products are actively promoted. Solutions and findings are made known to a large business audience at national and international events.

The Expert Initiative for the recovery of raw materials from waste and wastewater is implemented by the State Agency Umwelttechnik BW. The initiative is funded by the Federal State of Baden-Württemberg, independently of the ERDF Bioeconomy – Bio-Ab-Cycling funding call.

Contact person:

Dr.-Ing. Anette Zimmermann

Head of the Environmental Technology Team

Environmental Technology Agency BW

Contact

Unit resource efficiency, green tech, bioeconomy

Ministry of the Environment, Climate Protection and the Energy Sector Baden-Württemberg 70182 Stuttgart

Referat 14 – EU-Politik und -Förderung, Internationales, Under2 Coalition