Cooling lubricants reduce the friction between tool and workpiece during machining and forming. After mechanical processing, oil or fat remains on the workpiece. They must be removed completely for further surface treatment.

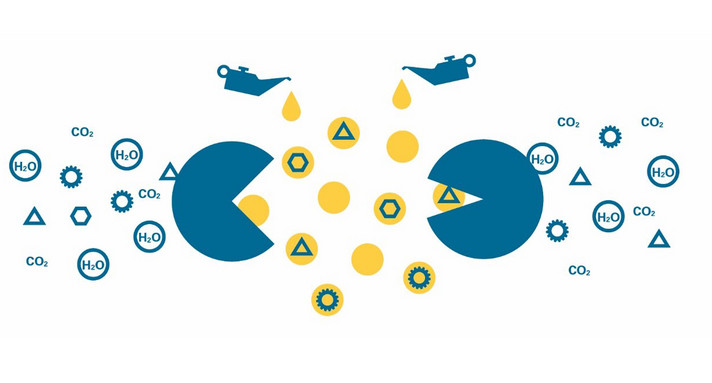

The principle of "biological degreasing" is to wash fats and oils off the surfaces, to emulsify them and then to break them down into carbon dioxide and water through the lipid metabolism of the oil-degrading microorganism.

Surface cleaning, and in particular the removal of oils and fats by means of biological cleaning, is an important cross-sectional technology, especially in the metal and plastic processing industry. It guarantees technically flawless further processing in the coating and surface treatment.

On the basis of experience with the biological mineral oil extraction after Tanker accidents, the idea of biological parts cleaning was born in the early 1990s in Europe. As a result of the transfer to industry, oils and greases, which are applied to metal parts using metalworking fluids, for example during the mechanical processing of metals, can now be removed from the surfaces without the use of solvents or strong acids (hazardous substances).

The principle of "biological degreasing" is to wash fats and oils off the surfaces, to emulsify them and then to break them down into carbon dioxide and water through the lipid metabolism of the oil-degrading microorganism. The cleaning solutions contaminated with fats and oils are regenerated. This means that they can be used again and again.

Another advantage of biological degreasing is that companies no longer have to dispose of oily concentrates or sludges. Some of the microorganisms involved in fat and oil breakdown themselves produce tensides, so-called bio-tensides. These emulsify the fats and oils that serve as food for the microorganisms so finely that they can "digest" them. This can reduce the addition of surfactants to the cleaning solution. The only limits are actually the entry of poorly degradable substances and synthetic oils, since these are generally not biodegradable. Since biological processes take place at moderate temperatures, bio-degreasing is often also used for energy efficiency.

The volume flows and cost advantages of the process are shown in the brochure "Bioeconomy - Green Clean" using three process examples (only in German language). Model workplace assessments, which you can download from the Baden-Württemberg Trade Inspectorate (only in German language), help with the use of the procedure.